What type of losses are in the Transformer?

In electrical transformers, several types of losses can occur, affecting their efficiency and performance. The primary losses are categorized as iron or core losses and copper or winding losses.

Iron losses consist of hysteresis and eddy current losses. Hysteresis loss is due to the lagging of the magnetic field strength behind the magnetizing force. Eddy current loss, on the other hand, is caused by circulating currents produced within the core as a result of the changing magnetic field.

Copper losses occur in the windings of the transformer due to the resistance of the copper conductors. copper losses depend on the load, hence they are also known as variable losses.

Other types of losses include stray losses, which are caused by stray fluxes induced by the primary winding in parts. These losses collectively determine the efficiency of a transformer and are critical factors in its design and operation.

The condition for maximum Efficiency of the Transformer only appears when copper losses are equal to the iron losses

Cu losses=Iron losses

Losses in Transformer

- Copper Losses

- Core Losses

- Dielectric Losses

- Hysteresis losses

- Iron losses

- Eddy's Current loss

- stray losses

Copper Losses

Copper loss is a type of loss that occurs in a conductor due to the ohmic resistance of the material. There are many types of conductors used for windings. Every conductor has internal resistance depending on length, area and type of material. when current flows in a conductor the I²R losses occur due to the ohmic resistance of the material. if the size of the conductor is greater then losses are small and if an area is small then losses are high just like the water pipe analogy.

Solution to reduce copper losses

Reducing copper loss in transformers is essential for improving their efficiency and performance. Here are some strategies to achieve this

- Increasing the conductor size reduces resistance, thereby lowering copper losses.

- Utilizing materials like high-purity copper or aluminium can decrease resistance in the windings.

- Careful design of the winding layout can minimize the length of conductors and reduce losses.

- Keeping the transformer cool helps maintain lower resistance in the windings. This can be achieved through better design and cooling systems.

- Operating the transformer close to its optimal load can minimize copper losses, as they are load-dependent.

- Using higher-quality insulation for wiring can reduce losses by preventing current leakage and overheating.

Iron losses

Iron losses in transformers are a combination of two main components Hysteresis losses and eddy current losses. Hysteresis losses occur due to the lagging of the magnetic flux behind the magnetizing force and are proportional to the frequency of the magnetic reversals and the volume and quality of the core material.

Eddy Current Loss Caused by circulating currents produced within the core as a result of the alternating magnetic field, this loss is proportional to the square of the thickness of the core laminations.

Both types of losses result in energy dissipation in the form of heat within the transformer's core and are considered when designing transformer efficiency and cooling systems.

W loss = total losses

Wei = Eddy's current losses

Whi = hysteresis losses

Solution to reduce Iron losses

Reducing iron losses in transformers is crucial for improving their efficiency and performance.

- Utilize high-grade materials like silicon steel, which has better magnetic properties and lower hysteresis losses compared to regular steel.

- Design the core to minimize resistance and heat loss. Larger cores allow more current to pass through with less heat generation, while materials with high permeability reduce eddy currents.

- Implement cooling fins or fans to dissipate heat effectively, maintaining safe operating temperatures and reducing thermal cycling.

- Use laminated cores to reduce eddy current losses, as they restrict the flow of these currents within the core.

- Select magnetic materials with low hysteresis loss to minimize energy dissipation during the magnetization and demagnetization cycles.

Hysteresis losses

Hysteresis losses in transformers are caused by the magnetization and demagnetization of the core material during each AC cycle.

This loss is due to the inherent property of ferromagnetic materials to resist changes in magnetization, known as magnetic hysteresis.

The energy lost in hysteresis is dissipated as heat, which can affect the efficiency and performance of the transformer.

To understand the Hysteresis loss we take help with the B-H curve, in this curve, current leads to the magnetic field which defines the magnetization and demagnetization effect.

Reducing hysteresis losses is crucial for improving the efficiency of electrical systems such as transformers, motors, and generators.

- Materials like silicon steel have a smaller area within their hysteresis loop, which leads to lower energy loss.

- Adding silicon to iron can reduce hysteresis losses, although the material becomes more brittle and harder to work with. A recommended proportion is 3% to 5% silicon.

- These processes can help align the grains in the magnetic material, reducing internal friction and thus hysteresis losses.

- Operating at a lower frequency can decrease hysteresis losses since the magnetic domains in the core material will have to switch direction less frequently.

- Keeping the flux density below the saturation point of the core material can prevent excessive hysteresis losses.

Eddy's current losses

Eddy current losses in transformers, also known as core losses, occur when the alternating magnetic field within the transformer's core induces currents in the core material itself.

These induced currents, called eddy currents, flow in loops and generate heat due to the resistance of the core material. This heat is a form of energy loss and is not used for any useful work.

The mathematical expression for eddy current loss is proportional to the square of the magnetic flux density, the square of the frequency of the magnetic field, and inversely proportional to the square of the thickness of the laminations

Pe = Ke Bm² * f² *t²*V

Solution to reduce Eddy's current losses

Eddy current losses in transformers can be mitigated by several methods. One effective approach is the use of laminated cores, which are thin layers of magnetic material separated by an insulating layer.

This lamination reduces the eddy current path and, consequently, the losses. Another method is to use materials with high resistivity, such as ferrites, which inherently have lower conductivity and thus reduce eddy current formation.

For winding designs, options like Litz wire, which consists of many thin wire strands individually insulated and twisted together, can be used to reduce losses at high frequencies.

Interleaved windings and half-layer designs are also beneficial in reducing these losses.

Dielectric Losses

Dielectric losses in transformers are energy dissipated as heat within the insulating material of the transformer. They occur due to the alternating electric field in the dielectric material of the transformer.

dielectric losses are frequency-dependent. For high-frequency applications, particularly above 1 GHz, careful consideration of the loss tangent is essential to minimize signal attenuation.

Reducing dielectric losses is important for improving the efficiency of electrical systems. One effective strategy is to use materials with a lower loss tangent.

Regular testing and maintenance of insulating materials, such as transformer oil, can also prevent deterioration that leads to increased dielectric losses.

Stray Losses

Stray losses in transformers are a type of energy loss that occurs outside the core and windings. These losses are caused by leakage flux that does not contribute to the transformation process.

|

| Stray Losses |

Solution to reduce dielectric losses

Stray losses can be minimized by careful design that reduces leakage flux and by using materials with lower magnetic permeability.

Efficiency of transformer

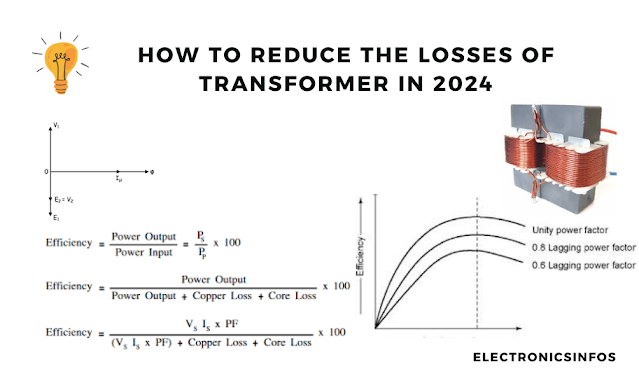

The efficiency of a transformer is defined as the ratio between the output and the input power is called the efficiency of a transformer. the output of a transformer is always less than the input power because of the losses of a transformer.

Efficiency = output/input

Efficiency = output/output + losses

The losses consist of iron loss and copper loss. the value of the iron loss is the overall contact from no load to full load. the copper loss depends on the load because it changes from no load to full load.

The cooper loss is directly proportional to the I²R losses. the efficiency of a transformer is varied from 95-98% on full load. the efficiency also depends on the design and size of the transformer.

The efficiency of a transformer is maximum when both copper and iron losses are equal for a specific load.

Conclusions

Reducing losses in transformers is important for improving their efficiency. At the design stage, several strategies can be used to minimize these losses. optimizing the core dimensions can help in reducing no-load losses which are primarily dependent on voltage and frequency.

With advancements in materials and design techniques, transformers are becoming more efficient, contributing to energy savings and reduced operational costs.

Frequently Asked Questions: FAQS

What are the main types of losses in transformers?

How can I reduce copper losses in transformers?

What are some techniques to reduce iron losses in transformers?

Does operating temperature affect transformer losses?

Are there specific maintenance practices to reduce losses in transformers?

Can transformer design modifications help in loss reduction?

Are there any advancements in transformer technology aimed at reducing losses?

What role does load management play in reducing losses?

Are there financial benefits to reducing losses in transformers?

How can I determine the effectiveness of loss reduction measures in my transformers?

Related Posts

Single Phase Transformer Vs Three Phase

Transformer

EMF Equation Of Electrical Transformer

What is a Step-Up Transformer?

.png)

0 Comments

please do not insert spam links