What is an Electrical Transformer?

|

| 15 Main Parts of Electrical Power Transformer |

Parts of the Electrical Transformer

- core

- Steel tank

- Windings

- Conservator

- Breather

- Thermometer

- pressure relief pipes

- Valves

- Buchholz Relay

- Bushings

- Tap changing switch

- Oil gauge

- Radiator

- Cooling fans

- Oil pumps

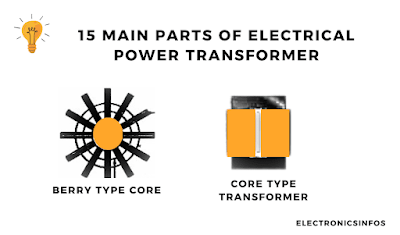

core of transformer

The core plays an important role in transformers due to its ability to transfer energy between the primary and secondary windings. The core provides a closed magnetic path in the circuit. The core's main purposes are reducing eddy current losses and providing a consistent magnetic path. Each core sheet is insulated with a laminating medium with a thickness of 0.35mm at 50 Hz and 0.5mm at 25 Hz frequencies. The core is constructed with laminated Silicon steel whose purpose is to reduce eddy current and magnetizing current. There are different types of cores are constructed as per transformer requirements.

|

| 15 Main Parts of Electrical Power Transformer |

In standard practice, a single-phase transformer core consists of 2 legs and a three-phase transformer core consists of 3 legs. The core is constructed circular and rectangular depending on the capacity of the transformer. This laminated core is also tight with the help of bolts.

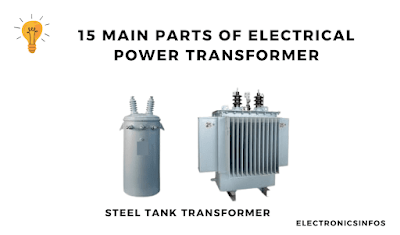

Steel tank of Transformer

The steel tank of a transformer is used to protect the transformer's core and windings. It is made of high-quality steel to withstand mechanical stress, corrosion, and environmental factors. This tank is filled with insulating or mineral oil that provides insulation and cooling. There are different types of steel tanks including

|

| 15 Main Parts of Electrical Power Transformer |

Types of Steel Tank

- Plain Steel Sheet Tank

- Tube Tank

- Tank with separate coolers

- Transformer Oil Tanks without a cooler

- Radiatorpanel type tanks

- Tubular cooling-type tanks

- Corrugated wall-type transformer tanks

- Pressed steel tank

- Welded steel tank

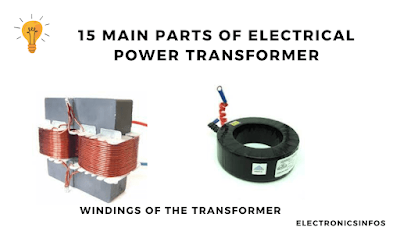

Windings of the Transformer

A single-phase transformer consists of one primary and secondary winding and a three-phase transformer consists of three primary and three secondary windings. These winding are connected in proper sequence. The windings are constructed in discs, helical coils, springs, Cylindrical and foil type. we use copper and aluminium material in the winding.

|

| 15 Main Parts of Electrical Power Transformer |

Windings Types of Transformer

- Disc Type Winding

- Helical Type winding

- Springs Type winding

- Cylindrical Type winding

- Foil Type winding

- Cross over Type winding

- Aluminium Type winding

|

| 15 Main Parts of Electrical Power Transformer |

Conservator of transformer

A conservator is a small cylindrical tank on top of the main tank in a transformer. It is connected to the main tank via a pipe. In transformers with a rating above 1MVA, a Buchholz relay is typically installed between the conservator tank and the main tank.

|

| 15 Main Parts of Electrical Power Transformer |

The conservator helps to maintain a constant oil level within the transformer and prevents the entry of moisture and air into the main tank.

The main function of a conservator is

- When oil is heated and expended it provides a space.

- It reduced the oxidation to reduce the oil surface area.

Advantages of Conservator

- The conservator provides extra space for the expansion and contraction of transformer oil as it heats up or cools down during operation.

- The conservator helps regulate the temperature of the transformer oil.

- Many conservators are equipped with oil level indicators and alarms, allowing for continuous monitoring of oil levels.

- The use of a conservator improves the overall safety of the transformer.

Breather of Transformer

A breather is a device used in transformers to control the moisture content of the air in the oil. It consists of a container filled with desiccant material, such as silica gel, that absorbs moisture from the air. The breather is typically installed on the vent or opening of the transformer tank.

|

| 15 Main Parts of Electrical Power Transformer |

Working of Breather

When oil expands due to heat, the air is expelled from the tank, and when oil contracts, the air is drawn in from the environment. One end of the breather is connected to the conservator tank. Inside the breather, there is a box filled with silica gel. When air enters the tank, it may contain moisture, which can adversely affect the insulation of the winding. To prevent this, silica gel absorbs moisture from the incoming air, ensuring that only dry air enters the transformer. As the silica gel absorbs moisture, its colour changes from blue to pink, indicating that it needs to be replaced.

Advantages of Breather

- Breathers control the moisture content of the air.

- Breathers help prevent insulation deterioration.

- Breathers also help filter out other airborne contaminants, such as dust, dirt, and debris.

- Many modern breathers use eco-friendly desiccant materials, making them environmentally friendly solutions for moisture control in electrical equipment.

Thermometer

A thermometer is a device used to measure the temperature of the transformer's components, particularly the transformer oil and winding temperatures.

Types Of Thermometer

- Dial Thermometer

- Digital Thermometer

- Winding Temperature Indicator (WTI)

- Oil Temperature Indicator (OTI)

When the temperature surpasses the threshold value, a signal is triggered, leading to the tripping of the transformer. A dial-type thermometer is employed within the transformer for temperature monitoring. This thermometer is linked to a sensor responsible for detecting the temperature of the transformer oil. The designated threshold temperature for the oil is set at 105 degrees Fahrenheit.

pressure relief pipes

Valves of Transformer

Different valves are used in the transformer to fill the oil, Drain the oil, Filter the oil and sample the oil. Valves in transformers are mechanical devices used to control the flow of oil and gas.

|

| 15 Main Parts of Electrical Power Transformer |

Types of Valves

- Pressure Relief Valves

- Gas Release Valves

- Drain Valves

- Check Valves

- Isolation Valves

Buchholz Relay

Buchholz is a gas-operating relay that protects the transformer from bursting. It's connected between the main tank and the conservator. It consists of two floats. one float is operated in an emergency condition and connected to the trip circuit. The other float generates an alarm signal. when the oil level is low or another internal fault appears in the transformer the gases are produced due to the decomposition of insulating material. Due to the lightweight of the gas, it moved to the upper side and operated the Buchholz relay float. This float is connected to the alarm circuit and trips the circuit.

|

| 15 Main Parts of Electrical Power Transformer |

Advantages of Buchholz Relay

- Early Fault Detection

- Protection Against Major Faults

- Reduced Downtime

- Improved Safety

- Enhanced Transformer Lifespan

- Monitoring Oil and Gas Conditions

Bushings of Transformer

The bushing is an insulating Component that connects the transformer windings to external conductors. bushings are made from porcelain and oil-filled capacitors. There are two types of busing one for L.T and another for H.T side. To protect from lightning arching horns are used on the upper and lower sides of bushings. There are two types of bushings w.r.t construction, Sealed condenser type oil-filled bushing with voltage ratings of 34.5 kV and plain bushings with voltage ratings of 25.

|

| 15 Main Parts of Electrical Power Transformer |

Tap changing switch

There are two types of Tap changing Switch

- Offload Switch

- On load Switch

The Offload tap changer adjusts the voltage ratio of the transformer winding. This adjustment is when the transformer is offline because altering the turn ratio can generate arcs within the windings. In a small transformer, the internally operated switch is used and for a large transformer, the external switch is used the transformer.

On load Switch

Onload Resistor-type and reactor-type tap changers consist of oil and vacuum switches. Resistor-type switches are used in the power distribution transformer. The Connection of Resistor-type Switch is connected to the star and delta. In the star connection, the voltage ratings are between 66KV and 30MVA in the delta connection, the voltage rating is between 66KV and 40MVA.

|

| 15 Main Parts of Electrical Power Transformer |

Features of Tap changer switch

- Voltage Regulation

- Load Compensation

- Multiple Tap Positions

- Automatic or Manual Operation

- On-Load Tap Changers (OLTC)

- Efficient Voltage Management

Oil gauge of Transformer

Oil gauges are used to measure the level of the oil. oil gauge is normally a dial-type in which a pointer indicates the transformer oil. the one advantage of dial type is we can easily measure the oil level. oil gauge is used in the medium level of the transformer.

|

| 15 Main Parts of Electrical Power Transformer |

Types of Oil gauge

- Dial-Type Gauges

- Digital Gauges

- Float-Type Gauges

- Magnetic Gauges

- Capacitance Gauges

- Ultrasonic Gauges

Radiator of Transformer

Radiators are used if transformer ratings are above 50KVA. Radiators are used with the main tank of the transformer. This consists of pipes and tubes that increase the surface area of the tank. Radiators are used for the cooling purpose of transformer oil. this method is also called ONAN(Oil natural and Air natural).

|

| 15 Main Parts of Electrical Power Transformer |

Types of Radiator

- Pressed Steel Radiators

- Welded Steel Radiators

- Extruded Aluminum Radiators

- Corrugated Fin Radiators

- Fin-and-Tube Radiators

- Cast Iron Radiators

Cooling fans of Transformer

Cooling fans in transformers are mechanical devices used to enhance the cooling process. Cooling fans help circulate air over the transformer's cooling elements, such as radiators or cooling fins. Cooling fans maintain optimal operating temperatures by regulating the airflow Many modern cooling fans are equipped with automatic control systems that adjust fan speed based on temperature sensors. Cooling fans are used in the ratings of 1MVA to 26MVA.

|

| 15 Main Parts of Electrical Power Transformer |

ONAF(Oil Natural And air forced) System

Types of Cooling Fans

- Axial Fans

- Radial Fans (Centrifugal Fans)

- Mixed Flow Fans

- Forced Draft Fans

- Induced Draft Fans

- Variable Speed Fans

- High-Efficiency Fans

Oil pumps of Transformer

Oil pumps in transformers are mechanical devices that circulate the transformer oil within the tank. Oil pumps ensure the continuous circulation of transformer oil to regulate the core temperature, windings, and other internal components. They contribute to efficient cooling, especially during periods of high load or ambient temperature.

|

| 15 Main Parts of Electrical Power Transformer |

Many modern oil pumps are equipped with automatic control systems that monitor oil temperature and flow rate.

Types of Transformer Oil Pumps

- Axial Pumps (For Force cooling system)

- Axial Pumps(For Radiator cooled system)

- Angle type Pumps

- Traction Pumps

.png)

0 Comments

please do not insert spam links